OEM Plastic Injection Mold and Related Part for Medical Equipment

Xiamen Stick Industry is a company has 16 years' experience on plastic injection and has a pro engineer team helping cus

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | STK-PLS-024 |

| Material Availble | PP, PA, PE, ABS etc. |

| Delivety Time | 5-25days |

| Size | Customer Drawings |

| Payment | T T50%Deposit |

| Quality | Professional Inspection |

| OEM & ODM | Welcome |

| Drawing Formats | Igs, Step, X-T, Pdf, JPG, Dxf, Dwg |

| Color | Customized |

| Transport Package | Standard Export Packing or as Per Request |

| Specification | As per customer inquirement |

| Trademark | Customized or STK |

| Origin | China |

| HS Code | 3926909090 |

| Production Capacity | 50, 000PCS/Mouth |

Product Description

Xiamen Stick Industry is a company has 16 years' experience on plastic injection and has a pro engineer team helping customers with any problem. We are one of leading ISO 9001: 2000 certified manufacture of mold design and fabrication that include plastic molds, plastic injection parts and plastic injection molding in China.The picture shown is the customized product we make for our customer, for reference only. Any OEM service is welcomed.

Company Advantage:

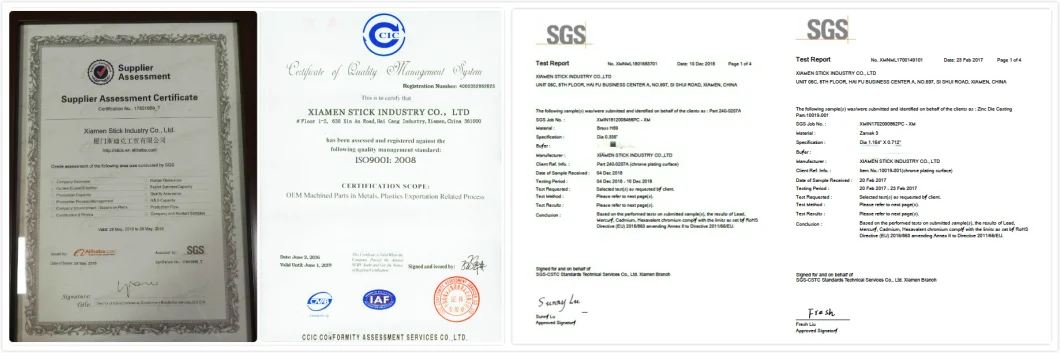

1. ISO 9001: 2015 certified

2. Advanced equipment and excellent R& D Team

3. Highly skilled manufacturing process

4. A broad variety of ODM& OEM product range

5. Strict quality Control System

6. Software for specification drawings: Pro/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM

High quality and fair price is highly strictly controlled here.

Plastic Product Range:

1. Automotive Parts

2. Household Products

3. Electronic Accessories

4. Industrial Components

5. Medical Parts

6. Others

Why Choose Us:

1. Founded in 2004, Cover an area of 10000 sqms Plant; Provide OEM/ODM Service

2. Certified by ISO90001, SGS,CE,UL etc

3. Over 10 years experience in Mold Making & Plastic Injection Parts Mass Production

4. Integrating R&D, QC System & Marketing Sales.

5. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis, Trial & mass production to Final mold assembly & shipment.

| Plastic Injection Molding Capacity | |

| Product Name | Plastic Parts for Medical Equipment |

| Material | PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc. |

| Mold Cavity | Single or Multi-cavity |

| Mold Base | LKM or Equivalent Standard mold base |

| Core Steel | NAK80 Prehardened steel,718, 718H, P20, S136 etc. |

| Injection Machine Size | 40 sets range from 80Tons to 1400Tons |

| Tolerance | +/-0.1mm |

| Max Mold Size | 1500mm X 1300mm |

| Product Unit Weight | From 0.1gram to 10,000grams |

| Tooling Lead-time | 3-7 weeks |

| Production Lead-time | 4-6 weeks |

| Surface Treatment | Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc |

| Mold Life | 50000 shots -500000 shots |

| Brand | STK or Customized |

| Delivery Time | In about 30 days for new production |

| Packing | Standard export packing or customized |

| MOQ | 1000 pcs |

| FOB port | Xiamen, China |

| Shipment | Air or Sea |

Plastic Materials Applies:

| Material Name | Features | Applications |

| PP | Lightweight, Heat Resistance, High Chemical Resistance, Scratch Resistance, Natural Waxy Appearance, Tough and Stiff, Low Cost | Automobile (Bumpers, Covers, Trim), Bottles, Caps, Crates, Handles, Housings. |

| POM | Strong, Rigid, Excellent Fatigue Resistance, Excellent Creep Resistance, Chemical Resistance, Moisture Resistance, Naturally Opaque White, Low/Medium Cost | Bearings, Cams, Gears, Handles, Plumbing Components, Rollers, Rotors, Slide Guides, Valves |

| PC | Very Tough, Temperature Resistance, Dimensional Stability, Transparent, High Cost | Automobile (Panels, Lenses, Consoles), Bottles, Containers, Housings, Light Covers, Reflectors, Safety Helmets and Shields |

| PS | Tough, Very High Chemical Resistance, Clear, Very High Cost | Valves |

| ABS | Strong, Flexible, Low Mold Shrinkage (Tight Tolerance), Chemical Resistance, Applicable for Electroplating, Naturally Opaque, Low/Medium Cost | Automobile (Consoles, Panels, Trim, Vents), Boxes, Gauges, Housings, Inhalers, Toys |

| PA6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Bearings, Bushings, Gears, Rollers, Wheels |

| PA6/6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Handles, Levers, Small Housings, Zip Ties |

| PBT,PET | Rigid, Heat Resistance, Chemical Resistance, Medium/High Cost | Automobile (Filters, Handles, Pumps), Bearings, Cams, Electrical Components (Connectors, Sensors), Gears, Housings, Rollers, Switches, Valves |

| PVC | Tough, Flexible, Flame Resistance, Transparent or Opaque, Low Cost | Electrical Insulation, Household wares, Medical Tubing, Shoe Soles, Toys |

| HDPE | Tough and Stiff, Excellent Chemical Resistance, Natural Waxy Appearance, Low Cost | Chair Seats, Housings, Covers, Containers |

| PMMA | Rigid, Brittle, Scratch Resistance, Transparent, Optical Clarity, Low/Medium Cost | Display Stands, Knobs, Lenses, Light Housings, Panels, Reflectors, Signs, Shelves, Trays |

Company Information:

Our main production area is equiped with 40 molding machines of various size,

ranging from 80 tons to 1400 tons clamping pressure.

This provides us with teh capability to mold shot weights from 0.1 gram to over

10000 grams with flexible production runs.

Plastic Injection Equipment List:

| Equipment | QTY | Origin |

| Injection Machine | 40 SETS | Taiwan / China |

| CNC Machine Center | 5 SETS | Taiwan / China |

| EDM | 6 SETS | China |

| EDM Mirror | 1 SETS | Japan |

| Wire Cutting | 5 SETS | Taiwan |

| Grinding Machine | 3 SETS | China |

| Milling Machine | 10 SETS | China |

| Drilling Machine | 15 SETS | China |

Packing:

Certificate:

Exhibition:

FAQ:

Q1. Can I have a sample order ?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What's your packing?

A:Full consideration of practical situation: foam/wooden box, anti-rust paper, small box and carton, etc.

Q3. Do you have any MOQ limit for led light order?

A: Low MOQ, 1pc for sample checking is available

Q4. What do I need for offering a quote ?

A: Please offer us drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q5. Are you trading company or manufacturer ?

A:We are factory, with about fifteen years experience of mould design and mold making, production. We are 12 years Gold Supplier of Alibaba.We have established the quality management system conforming to ISO 9001:2008.We are absolutely worth your trust.

Q6. How long will it take for production?

A: It depends on the quantity and the complexity of the products you want.But the normal products we ensure can deliver on the day when you pay the money.

Q7: Do you accept customized?

A: Of course. Mould is a customized project. You can tell us your request about mould material, color, size and so on.

Q8: What is your terms of payment?

A: Mold :50% deposit +50% after the samples is approved.

Batch production: 30% deposit +70% before shipment.

Related Products

-

![Professional Gallon Pet Preform Mold Maker 5 Gallon 3 Gallon Pet Preform Mold 20L Bottle Mold]()

Professional Gallon Pet Preform Mold Maker 5 Gallon 3 Gallon Pet Preform Mold 20L Bottle Mold

-

![China 500ml 1L 2L 3L 4L 5L 10L Extrusion Blowing Molding Moulding Tank Barrel Drum Plastic HDPE Bottle Blow Mold Mould]()

China 500ml 1L 2L 3L 4L 5L 10L Extrusion Blowing Molding Moulding Tank Barrel Drum Plastic HDPE Bottle Blow Mold Mould

-

![Double Plate 8 Cavity Needle Valve Gate Preform Mould]()

Double Plate 8 Cavity Needle Valve Gate Preform Mould

-

![Plastic Water Bottles Oil Bottles Pet Preform Mould]()

Plastic Water Bottles Oil Bottles Pet Preform Mould